Melfi Batch© Gravimetric Feeder Controllers

Looking to improve your batching accuracy?

Melfi Batch© is the next generation of PAC/PLC-based Gain-in-Weight, Loss-of-Weight, Weighbelt and Flowmeter automated batching controllers. The system is designed to directly replace the proprietary microprocessor equipment supplied by any of the popular LIW feeder manufacturers. .

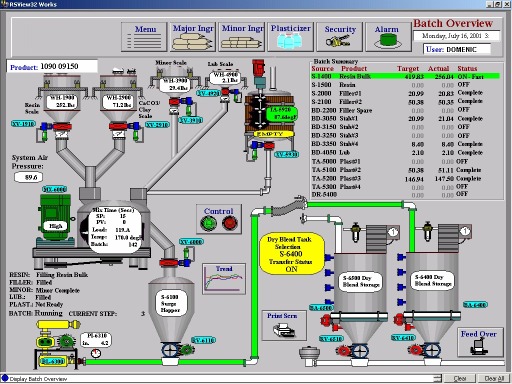

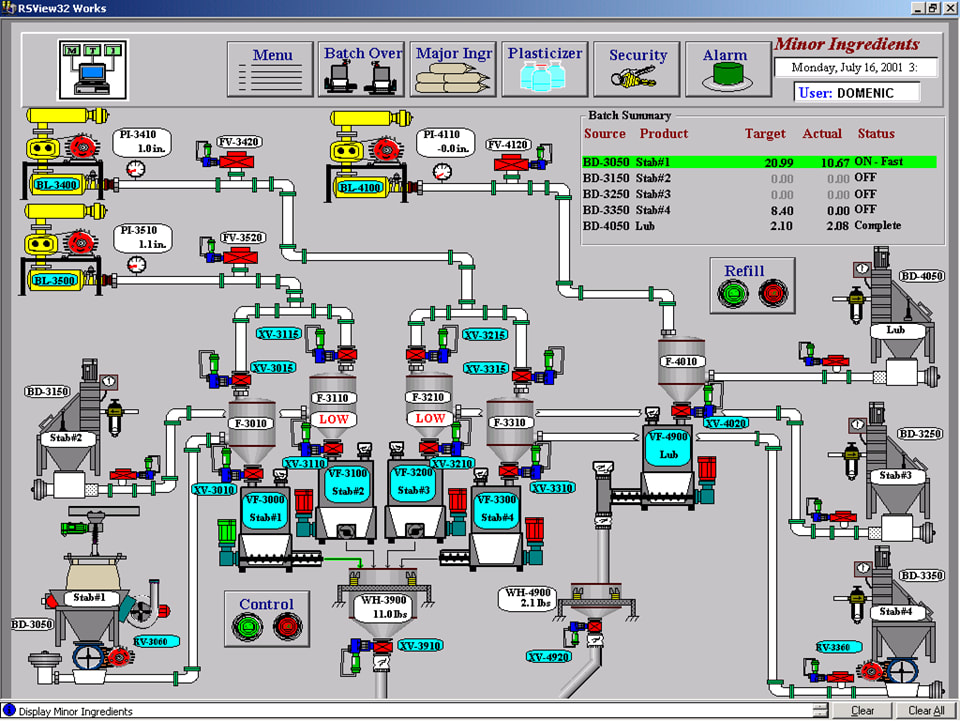

The Melfi Batch© PAC/PLC controller has been developed around the Rockwell ControlLogix and CompactLogix hardware platforms using standard RSLogix5000 programming software with Rockwell Automation FTview HMI. Field communications to the loadcell amplifiers are open standard Ethernet/IP components. We have created a cost effective solution using non-proprietary hardware to simplify the gravimetric batching control process.

Melfi Batch© is the next generation of PAC/PLC-based Gain-in-Weight, Loss-of-Weight, Weighbelt and Flowmeter automated batching controllers. The system is designed to directly replace the proprietary microprocessor equipment supplied by any of the popular LIW feeder manufacturers. .

The Melfi Batch© PAC/PLC controller has been developed around the Rockwell ControlLogix and CompactLogix hardware platforms using standard RSLogix5000 programming software with Rockwell Automation FTview HMI. Field communications to the loadcell amplifiers are open standard Ethernet/IP components. We have created a cost effective solution using non-proprietary hardware to simplify the gravimetric batching control process.

Controller Features

- Add/Loss-In-Weight Batch Feeder Selection

- Automatic In-Flight (Pre-Act) Adjustment

- Fast Feed/Dribble Feed Control

- Adjustable Digital Signal Filtering

- Select Alarm Enable/Disable/Shutdown

- Adjustable Processing Sampling

- Select Alarm Enable/Disable/Shutdown

- Hardy WAVERSAVER® Vibration filtering

- FTview Human Machine Interface (HMI)

- Standard Components, Available Locally

- Field Expandable for Unlimited Feeders

- Programming IEC 1131-3 Compliant

- Remote Support via Modem or VPN

- Interoperability: control, process monitoring, communications, information collection, client/server based recipe and reporting all within one completely integrated and scalable batching solution.